Products Overview Showcasing Our Work

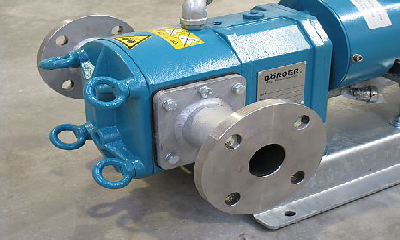

Börger

The Börger product range comprises Rotary Lobe Pumps

and Macerating Technology for wastewater,

endless industrial applications and farming and includes

supplementary products for agriculture/farming and biogas.

MPI (Maintenance In Place) Construction: allows the quick and convenient access to all fluid wetted parts without any removal of pipes, drives or ther components of the pump unit by your own staff.

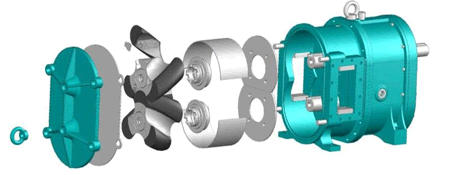

Operation Principles of the Börger Rotary Lobe Pump

Self-priming, valve-less positive displacement pump

Dual-shaft, parallel-axle design

Counter rotating shafts, guided by external synchronizing gear

The displacement rotors operate with minimized axial and radial clearance

Rotors and casing completely isolate the suction and pressure areas of the pump

For viscous, solids-loaded, abrasive, shear-sensitive products

Gentle, pulsation-free conveying

Reversible by changing direction of rotation

10 Rotor Designs with numerous Materials – to fit your Application

Block construction

Timing gear in a one-piece construction housing with a strong bearing frame and durable gear wheel pairing.

Compact Construction

High performance in a compact design.

Interior Pump Protection

Protection plates and liners available from a selection of hardened steel, stainless steel, plastic or ceramic.

Life Cycle Costs

For the customer, capital cost, energy consumption, maintenance and downtime as well as replacement part pricing levels compare excellently with all other displacement pumps.

MIP

Maintenance In Place: Replacement of wear parts in the blink of an eye, in-situ by service personnel. The way to go in the reduction of maintenance and downtime.

Pump Housing

Made from high-quality cast iron, ductile iron, stainless steel or in duplex quality. Thanks to MIP construction an almost limitless operational lifetime is achieved.

Quench

The quench and control liquid filled intermediate chamber, between the pump casing and the timing gear, provides a high degree of safety and is supplied by Börger as standard.

Quick release cover

This is the entrance door to the interior of the pump and provides the quickest possible access to all parts in contact with the pumped medium.

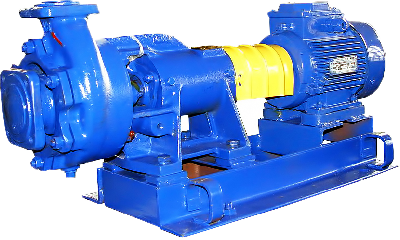

Rotary Lobe Pumps

Self priming, valveless displacement pumps guarantee pulsation-free and smooth flow patterns; reversible flow by switching the rotation direction.

Rotor Materials

Coatings to suit intended usage made from elastomers, plastic, all-metal including stainless steel.

Rotors

The patented rotors with quickly exchangeable tips, elastomer coated or adjustable; scew design for pulsation-free pumping.

Shaft Seal

Supplied as standard with strong mechanical seal in different constructions and materials, optional with multiseal or packing. The new DPL size double-acting mechanical seal is especially designed for pumping difficult and hazardous, often viscous media.

Smooth Pumping Action

Large bucket geometry and short passage through the pump provide a smooth transfer of the pumped fluid.